Nickel Alloys - A Durable and Safe Choice for Your Needs.

Introduction

Do you know what nickel alloys are? Nickel alloys are metals that contain nickel as one of the primary elements. These metals are known for their strength, durability, and wear-resistance, which makes them an excellent choice for various applications such as aerospace, automotive, construction, and many more. We will introduce you to the advantages of Walmay Metal nickel alloy metals and how they can be used for several applications.

Nickel alloys are advantageous because they have an unique combination of properties that make them ideal for different applications. They are highly resilient and can withstand extreme temperatures and corrosive environments. Additionally, Walmay Metal nickel alloy pipe is lightweight, ductile, and have excellent electrical conductivity and magnetic properties.

The continual innovation in nickel alloy technology is making it possible to customize alloys properties to fit specific applications. This innovation not only makes Walmay Metal nickel alloy coil more versatile but also increases their use in new applications. Advanced research and development have led to new heat-resistant alloys that can withstand temperatures above 1000℃. This makes them ideal for the production of jet engine turbines, gas turbines, and other high-temperature applications.

Walmay Metal nickel alloys are safe to use because they maintain their strength and corrosion-resistance under different environmental exposures. They are also widely used in healthcare because of their biocompatibility, which means that they are not harmful to human health. Additionally, they are non-magnetic, making them suitable for medical applications such as magnetic resonance imaging.

Nickel alloys have a wide range of applications. They are widely used in industries such as aerospace, automotive, construction, medical, and many more. In aerospace, nickel alloy tubes are used in the production of jet engines and other aircraft components. In the automotive industry, they are used in the Walmay Metal manufacturing of exhaust systems and turbochargers. In construction, nickel alloys are used in the production of roofing materials, electrical wiring, and other building components.

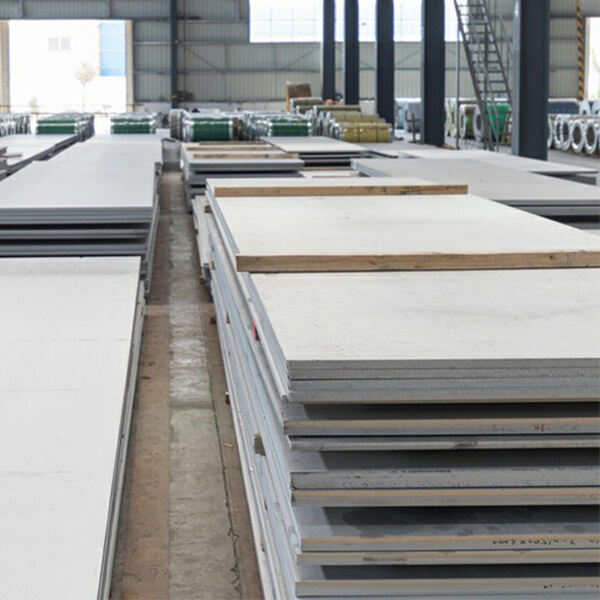

Walamy's products are packaged shipped according to international standards. Third-party testing: We able to support our customers in nickel alloy metals inspections of quality checking the factory and warehouse. After-sales Support: We offer 24-hour services good after-sales assistance.

We are a part of ISO 9001:2015-certified management system. Raw materials sourced from suppliers that meet ASTM, BS EN DIN standards. Our nickel alloy metals undergoes rigorous inspection to make sure meet the customer's specifications within tolerances. We also cooperate accrediting labs for test of materials, chemical analysis, and other tests.

Walamy With more 15 years' nickel alloy metals, established itself as a top steel exporter and distributor, offering quality steel customers across the world. We invite you contact us if require a small quantity. The Best Service: Every year, Walamy provides customers with most effective product advice as well as top-quality manufacturing services. You can count on our efficient team of experts take care of your needs special needs if you are looking for competitively priced and quality products. Think about your strategy first, Walamy is a great choice.

The capacity Walamy's supply is greater than 5,000 tons. every steel product is nickel alloy metals to the highest qualityWe have the unique ability to provide flexible options meet your specific needs. We understand how to combine appropriate sizes and grades in order to satisfy your needs. We offer custom-designed processing service. We can also cut it to the dimensions you require, and supply various grades in diameters, thicknesses, diameters.

Our professional sales team answers your questions within 24 hours.

Copyright © Wuxi Walmay Steel Co.,Ltd All Rights Reserved