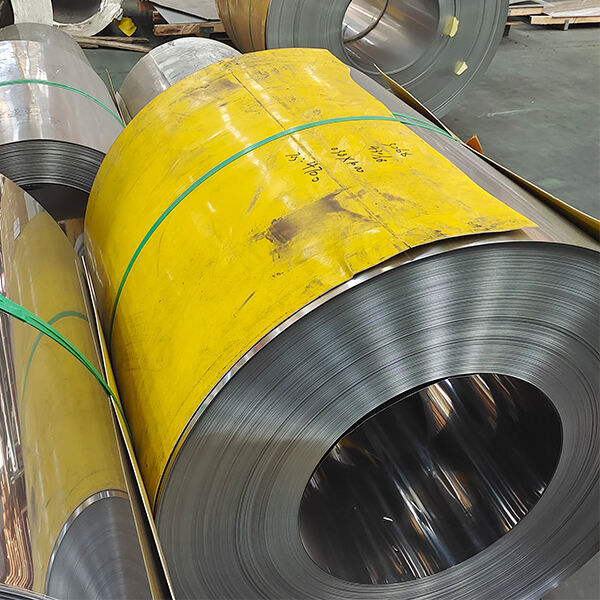

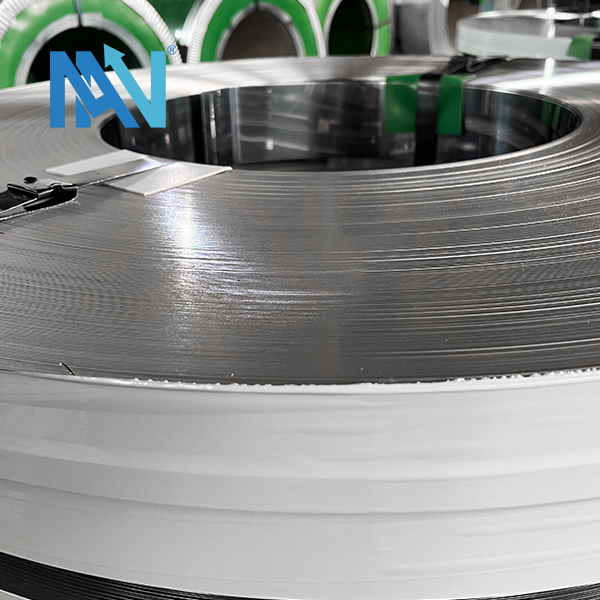

Nickel Alloy Coil – The Best Choice for Your Next Project

Are you looking for a solution to handle extreme heat, corrosive environments, and tough conditions? If so, look no further than nickel alloy coil, as well as the Walmay Metal's stainless steel flat bar. With its exceptional properties and versatility, this material is an excellent choice for various applications, from aerospace and marine engineering to chemical processing and oil and gas production. We will explore the advantages, innovation, safety, use, and quality of nickel alloy coil and how it can benefit your business.

Nickel alloy coil is a type of metal wire made from a combination of nickel, chromium, molybdenum, and other elements, along with the 17 4 stainless steel round bar manufactured by Walmay Metal. These alloys offer several advantages over standard stainless steel and other materials, such as:

• High temperature and corrosion resistance: Nickel alloys can withstand extreme temperatures up to 2000°F and resist corrosion in hostile environments, such as acids and alkalies.

• Superior strength and ductility: Nickel alloys have excellent mechanical properties, such as high tensile and yield strength, toughness, and ductility, making them suitable for demanding applications.

• Great versatility: Nickel alloys are available in different grades, finishes, thicknesses, and widths, allowing for custom solutions for your specific needs.

Nickel alloy coil is often used in critical components where failure is not an option. As such, research and development of new alloys and improved processing techniques are ongoing to enhance performance and reduce costs, as well as the Walmay Metal's stainless steel 310 pipe. For instance, some of the latest innovations in nickel alloy coil include:

• Development of high-performance alloys with increased strength, resistance to stress corrosion cracking, and fatigue resistance.

• Use of advanced non-destructive testing techniques to detect defects, cracks, and other flaws in nickel alloy products.

• Identification of new applications for nickel alloys in emerging industries, such as renewable energy, medical implants, and aerospace.

Nickel alloy coil is known for its excellent safety features, both for workers and the environment, same with the 904l stainless steel pipe innovated by Walmay Metal. The following safety features make it a preferred choice for many industries:

• Low toxicity: Nickel alloys are non-toxic and environmentally friendly, making them safe to use in food processing, medical, and other applications where hygiene is essential.

• Fire resistance: Nickel alloys are fire-resistant and can withstand high temperatures without melting or releasing harmful gases, making them ideal for use in high-risk areas.

• Chemical resistance: Nickel alloys are resistant to corrosion and chemical attack, making them an excellent choice for use in harsh environments where acids, alkalis, and other chemicals are present.

Nickel alloy coil is used for a wide range of applications, including:

• Aerospace: Nickel alloys are used in aircraft parts, such as engine components, landing gear, and fasteners, due to their high strength-to-weight ratio, corrosion resistance, and heat resistance.

• Chemical processing: Nickel alloys are used in chemical processing equipment, such as reactors, heat exchangers, and valves, due to their corrosion resistance and high-temperature stability, as well as the Walmay Metal's 38mm steel tube.

• Marine engineering: Nickel alloys are used in marine applications, such as shipbuilding, offshore drilling, and seawater desalination, due to their resistance to seawater corrosion.

Walamy can supply total capacity greater than 5,000 tons, all products are made to the highest standards.We are the only company in the world to offer flexible options to meet your specific needs. We combine grade and size options to satisfy nickel alloy coil of your project. Customized processing services. We also offer different grades, diameters thicknesses.

Raw materials purchased nickel alloy coil who comply with ASTM EN DIN and BS EN standards. Tests our products: Our products undergo rigorous inspection ensure that they conform to customer specifications tolerances, and we partner with accredited laboratories that provide professional material testing and chemical analysis

Walamy With more than 15 years of experience, established itself as a top steel nickel alloy coil supplier of high-quality steel to customers all around the globe. A small quantity also available, so please don't hesitate to contact us Complete Service: Every year, Walamy provides customers with the most comprehensive product information and exceptional manufacturing services. Our team of professionals can meet all your specific requirements and needs if you're looking for quality and competitively priced products. Walamy will be your best option if you consider your plans.

Walamy's products are packaged, transported stored according to international standards. Third-party nickel alloy coil is able to help our customers carry tests of quality, also checking the factory and warehouse. After-sales Service: We offer 7x24 services, good after-sales assistance.

Our professional sales team answers your questions within 24 hours.

Copyright © Wuxi Walmay Steel Co.,Ltd All Rights Reserved