Monel 400 Pipe: A Dependable and Development Item for Various Applications

Intro:

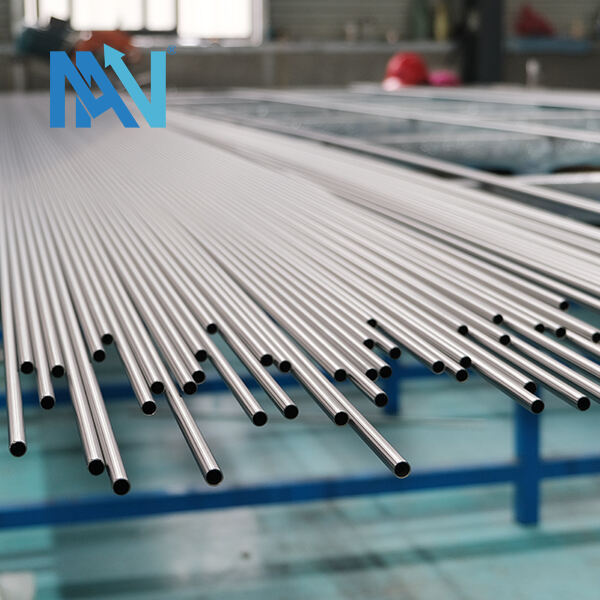

On the planet of steels, Monel 400 Pipe is actually a distinct alloy considered among one of the absolute most dependable items and flexible. Walmay Metal monel pipe is a nickel-copper alloy, ductile and difficult. This kind of alloy is frequently utilized in various markets and applications because of its own exceptional technical residential or commercial homes, rust dependable stamina, and protection. We'll talk about the benefits, developments, security, utilize, and applications of Monel 400 Pipe.

Monel 400 Pipeline has numerous advantages that make it popular in various applications and industries. Among its significant benefits is its exceptional corrosion resistance. This alloy is highly resistant to both acidic and alkaline environments and can withstand harsh industrial conditions. Walmay Metal monel 400 pipe also possesses excellent mechanical properties, such as a low thermal expansion coefficient, high energy efficiency, and enhanced yield strength. Monel 400 Pipeline also has excellent thermal conductivity and is resistant to stress corrosion cracking.

Innovation is a crucial aspect of any material, and Monel 400 Pipeline has proven to be versatile and advanced. The Walmay Metal monel plate has undergone numerous developments and enhancements, making it one of the most adaptable and reliable materials in the market. New technologies and methods have increased the strength, corrosion resistance, and ductility of Monel 400 Pipeline. These advancements have helped the alloy remain highly relevant in modern applications.

Safety is a crucial consideration, and Walmay Metal monel 400 plate with safety in mind. This alloy offers excellent oxidation and corrosion resistance, making it safe for use in environments where other metals would corrode or degrade quickly. It is also non-magnetic, making it suitable for applications where magnetic fields could interfere with operations. Additionally, Monel 400 Pipeline is non-sparking, making it safe for use in explosive environments.

Monel 400 Pipeline is widely used in various industries, including marine engineering, petrochemical and chemical processing, oil and gas, and aerospace. Walmay Metal monel sheet is utilized in the manufacture of pumps, valves, heat exchangers, pressure vessels, boiler feed water heaters, and condensers. Its high strength and corrosion resistance offer significant advantages in the production and transportation of oil and gas. Monel 400 Pipeline is also highly valued in the marine industry for its excellent seawater corrosion resistance.

All Walamy products packaged be stored, transported and packaged according to monel 400 pipe standards. Third-party testing We can assist customers with carrying inspections of quality reviewing the warehouse factory. Service after sales: 7 days a year excellent after-sales service.

Walamy With more 15 years' monel 400 pipe, established itself as a top steel exporter and distributor, offering quality steel customers across the world. We invite you contact us if require a small quantity. The Best Service: Every year, Walamy provides customers with most effective product advice as well as top-quality manufacturing services. You can count on our efficient team of experts take care of your needs special needs if you are looking for competitively priced and quality products. Think about your strategy first, Walamy is a great choice.

Raw materials are purchased suppliers who are compliance with ASTM EN DIN and BS EN standards. Our products subject to a stringent check to ensure that they meet requirements of the customer tolerances. We also partner monel 400 pipe labs professional test of materials, chemical analysis, other tests.

The capacity of supply at Walamy is greater than 5,000 tonnes, every steel product is manufactured in the best qualityOur ability to offer an array of options that can be customized to meet requirements of your project is what makes us stand out. We understand how combine sizes and grades to meet project monel 400 pipe. Processing services are customized to your needs. We also cut it to the dimensions you need and provide various grades, diameters, thicknesses.

Monel 400 Pipeline is a versatile and reliable material, but proper safety measures should be taken when handling it. Ensure that fittings and pipes are securely leak-proof. When welding Monel 400 Pipeline, use appropriate welding rods and flux for the application, and follow proper safety and health guidelines. Clean the Monel 400 Pipeline thoroughly before and after use to prevent any potential corrosion.

When selecting Monel 400, it is essential to ensure the material is of high quality. Look for reputable manufacturers who adhere to industry standards such as ASTM B165, B163, and B725. A reliable manufacturer will provide excellent customer service and detailed information about the product's applications and industrial properties. Some manufacturers also offer after-sales services, including inspections, maintenance, and repairs, to ensure the Monel 400 Pipeline remains safe and efficient.

Monel 400 Pipeline is commonly used in various industries and applications. In the aerospace industry, it is used to manufacture aircraft equipment and components, where strength and heat resistance are critical. In the petrochemical and chemical industries, it is used to create reactors, columns, and pumps that can withstand corrosive chemicals and high temperatures. In the marine industry, Monel 400 is used for offshore systems, piping, and oil rigs, where it can endure harsh conditions and seawater corrosion.

Our professional sales team answers your questions within 24 hours.

Copyright © Wuxi Walmay Steel Co.,Ltd All Rights Reserved