Alloy 690 Tube: The Safe and Innovative Choice for Your Needs

If you need a high-quality tube for your industrial or commercial application, look no further than alloy 690 tube. This versatile material boasts a wide range of benefits, including exceptional durability, corrosion resistance, and thermal stability. We'll explore everything you need to know about alloy 690 tube or even Walmay Metal nickel alloy metals, from its advantages and innovation to safety, use, and application.

Alloy 690 tube of Walmay Metal offers a number of advantages over other materials on the market. It is extremely resistant to corrosion, making it ideal for use in harsh environments where exposure to chemicals, salt, or other corrosive materials is common. It is also highly durable, able to withstand significant wear and tear without cracking, bending, or breaking. Additionally, its superior thermal stability makes it suitable for use in extreme temperatures, making it a reliable choice for use in a range of different industries.

Alloy 690 tube is the product of years of innovation in materials science and engineering same with Walmay Metal nickel alloy tube. Manufacturers have developed new techniques for producing this material in a way that maximizes its strength, durability, and resistance to corrosion and heat. These innovations have led to a stronger alloy, more flexible, and more reliable than ever before, providing businesses with a versatile and effective tool that can improve their output and performance.

In addition to its many advantages and innovative manufacturing processes, Walmay Metal alloy 690 tube is also known for its exceptional safety record. This material is highly resistant to fracture and other forms of structural damage, making it less likely to pose a risk to workers or equipment. Additionally, it is easy to handle and use, even in demanding industrial environments.

If you're considering using alloy 690 tube in your application this is same with Walmay Metal nickel 200 alloy, it's important to follow proper safety protocols and guidelines. Make sure you choose the right size and specifications for your needs, and always wear appropriate protective gear when handling or working with this material. Avoid using it in areas where it may be exposed to excessive heat or corrosive materials, and be sure to follow all relevant safety guidelines and industry best practices.

We operate an ISO 9001:2015-certified management system. Raw alloy 690 tube purchased from vendors that are compliance with ASTM, BS EN and DIN standards. Product testing: Our products thoroughly examined conformity to customer specifications tolerances and cooperate with accredited labs for expert material testing and chemical analysis.

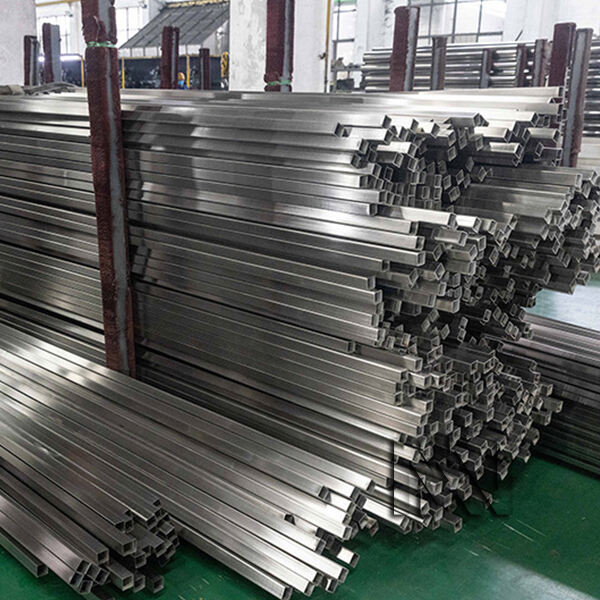

Walamy's supply capacity is more 5,000 tons. all steel products are made according to the highest standards.We have the unique ability to provide various options will fulfill your individual requirements. We alloy 690 tube how to combine the best grade size options in order to satisfy your needs. Customized processing services. can cut it to the size you require and offer variety of grades, diameters, and thicknesses.

With over 15 years of experience, Walamy grown into a leading alloy 690 tube supplier and exporter, supplying tons steel and providing top-quality steel products clients around the world. We invite you contact us if need small quantities. Walamy offers customers the best advice on manufacturing services and products throughout the year. Our expert team meet all your specific requirements and needs you're looking for affordable and high-quality products. Walamy is your ideal choice if you are looking at your plan.

Walamy's goods are packed accordance to international standard. Third Testing a third party: We help customers carry out quality inspections, inspect warehouse alloy 690 tube. After-sales Support: We offer 24-hour services good after-sales support.

Our professional sales team answers your questions within 24 hours.

Copyright © Wuxi Walmay Steel Co.,Ltd All Rights Reserved