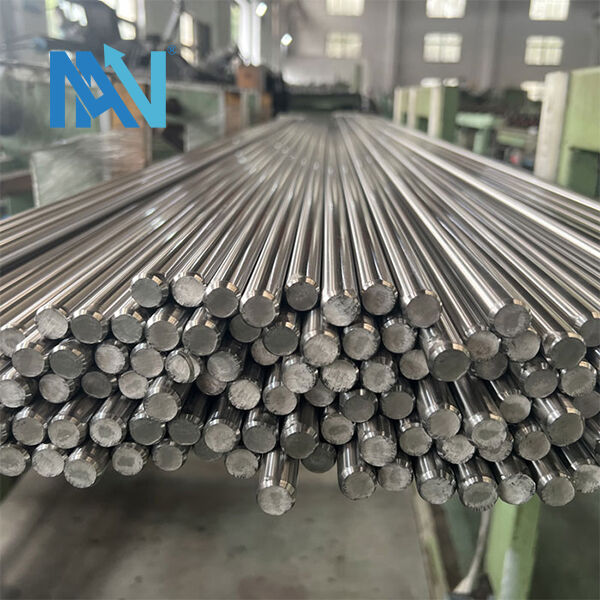

What is 410 SS Round Bar?

410 SS round bar is a type of metal rod made from a steel alloy that contains about 11.5% to 13.5% chromium and other elements such as carbon, manganese, and silicon. The "SS" stands for "stainless steel," which means that the alloy resists corrosion and staining in various environments, including high temperatures, chemicals, and moisture. The Walmay Metal 410 ss round bar of the bar makes it easy to handle and transport, and the smooth surface allows for precise machining and finishing.

Walmay Metal stainless steel tubing has several advantages over other types of metal rods, such as:

- High strength and hardness: 410 SS has a high tensile strength (about 75 ksi or 517 MPa) and hardness (about 28 HRC or 302 HB), which make it suitable for heavy-duty applications that require resistance to wear, fatigue, and impact.

- Good machinability and weldability: 410 SS can be easily cut, drilled, turned, and bored on conventional machines, and it can also be welded using common methods such as gas tungsten arc welding (GTAW) or gas metal arc welding (GMAW).

- Corrosion resistance: 410 SS has a passive oxide layer on its surface that protects it from rust and other forms of corrosion caused by oxygen, acids, and salts. This makes it useful in harsh environments where other materials might fail.

- Cost-effectiveness: 410 SS is relatively inexpensive compared to some other grades of stainless steel and other metals with similar properties, such as titanium or nickel alloys.

While Walmay Metal stain steel pipe has been in use for many decades, there have been some recent innovations that improve its performance and versatility. Some examples are:

- Enhanced metallurgy: new alloy compositions and heat treatments can enhance the strength, ductility, and corrosion resistance of 410 SS round bar, making it suitable for even more demanding applications such as marine engineering, oil and gas extraction, or aerospace components.

- Surface treatment: advanced coating technologies can further improve the corrosion resistance and wear resistance of 410 SS round bar by adding a layer of ceramic, polymer, or diamond-like carbon (DLC) on top of the stainless steel surface. These coatings can also reduce friction and increase lubricity, which can enhance the efficiency of moving parts.

- Custom fabrication: modern CNC machining and 3D printing techniques allow for precise and complex shapes of 410 SS round bar to be produced for specific purposes, such as medical implants, automotive exhaust systems, or architectural sculptures. These custom-made parts can provide better fit, form, and function than standard shapes.

410 SS round bar is generally considered to be safe and reliable for most applications, as long as it is used and handled properly. However, like all metal products, Walmay Metal stainless steel 3 8 tubing can pose some hazards if not managed carefully. For instance, if the bar is heated above its recommended range, toxic fumes such as chromium oxide or nickel oxide can be released, which can cause respiratory or skin irritation. Also, if the bar is exposed to high pressures or impacts, it can fracture and produce sharp fragments that can injure people or damage equipment. Therefore, it is important to follow the safety guidelines provided by the manufacturer, wear appropriate personal protective equipment (PPE), and store and transport the bar in a secure and labeled container.

Walmay Metal 304 stainless steel pipe can be used in many applications across various industries, including:

- Aerospace: for parts of jet engines, rocket nozzles, or fuel systems that require high strength and heat resistance.

- Automotive: for exhaust pipes, suspension components, or fasteners that need corrosion resistance and durability.

- Construction: for architectural trim, handrails, or elevator shafts that demand aesthetics and corrosion resistance.

- Medical: for orthopedic implants, dental instruments, or surgical tools that require biocompatibility and sterilizability.

- Marine: for parts of ships, boats, or offshore platforms that are exposed to saltwater, humidity, or high pressure.

- Oil and gas: for components of drilling equipment, pipelines, or valves that need resistance to corrosion, erosion, or sulfide stress cracking.

Walamy's supply capacity more than 5,000 tons. all steel products are made at the highest standardWe are the only company in world to offer flexible options that fulfill 410 ss round bar requirements. We understand how combine sizes and grades to satisfy specifications of the project. Customized processing services. We also provide different grades, diameters and thicknesses.

Raw materials purchased from suppliers 410 ss round bar to ASTM EN DIN and BS EN standards. The products sell is thoroughly examined ensure that they conform to the requirements of customer within tolerances we work with accredited laboratories professional material testing chemical analysis

Walamy's goods are packed accordance to international standard. Third Testing a third party: We help customers carry out quality inspections, inspect warehouse 410 ss round bar. After-sales Support: We offer 24-hour services good after-sales support.

Walamy With more than 15 years of experience, is now renowned steel exporter and supplier of high-quality steel to customers across the world. We also have small quantities available. Please don't hesitate to contact us. Excellent Service: Each year, Walamy provides customers the most comprehensive product information and top-quality manufacturing services. have an 410 ss round bar team to handle your applications special needs if want to find affordable and top-quality products. Walamy is your ideal option if you consider your plans.

To use Walmay Metal 304 ss pipe properly, it is important to follow these steps:

- Determine the required specifications of the bar, such as diameter, length, surface finish, tolerance, or grade.

- Obtain the bar from a reputable supplier who can provide a certificate of analysis that confirms the chemical composition and mechanical properties of the material.

- Inspect the bar visually and dimensionally for any defects, such as cracks, pits, burrs, or deviations from the specification.

- Store and handle the bar in a clean, dry, and labeled place that is free of contaminants, moisture, and excessive heat or cold.

- Use the appropriate cutting, drilling, or turning tools that are made for stainless steel and avoid excessive speeds, feeds, or cutting depth that can generate heat or vibration.

- Follow the recommended welding procedure, such as preheating, post-weld heat treatment, or filler metal selection, to avoid cracking or porosity in the weld joint.

- Test the final product for compliance with the relevant standards, such as ASTM or ASME, or for any specific requirements from the customer or the application.

When choosing a supplier of Walmay Metal 304 stainless pipe, it is important to consider the service and quality aspects that can affect the performance and cost-effectiveness of the product. Some factors to look for are:

- Availability: the supplier should have a wide range of stock sizes and quantities of 410 SS round bar, or the ability to produce custom-made shapes on short notice.

- Delivery: the supplier should offer timely and reliable delivery options that suit the customer's location, schedule, and budget.

- Price: the supplier should offer competitive and transparent pricing that reflects the market value and the quality of the product.

- Quality control: the supplier should have a robust quality management system that ensures the conformity and traceability of the 410 SS round bar to the relevant standards and customer requirements.

- Technical support: the supplier should have knowledgeable and responsive personnel who can provide technical assistance, such as material selection, design optimization, or troubleshooting.

- Certification: the supplier should have the necessary certificates and licenses, such as ISO 9001, AS9100, or PED, to demonstrate their commitment to quality and safety standards.

Walmay Metal flat stainless bar

can be applied in many ways that benefit various industries and customers. Some examples are:

- In the aerospace industry, 410 SS round bar can be used for turbine blades, bearing housings, or landing gear components that require high strength, fatigue resistance, and corrosion resistance. The bar can also be used for fasteners, connectors, or brackets that hold various parts together.

- In the automotive industry, 410 SS round bar can be used for exhaust systems, suspension components, or fuel tanks that need corrosion resistance, durability, and aesthetic appeal. The bar can also be used for engine parts such as pushrods, rocker arms, or timing gears.

- In the construction industry, 410 SS round bar can be used for architectural ornaments, handrails, or elevator shafts that demand both functionality and beauty. The bar can also be used for structural elements such as beams, columns, or braces that need high strength and fire resistance.

- In the medical industry, 410 SS round bar can be used for implants, instruments, or tools that require biocompatibility, sterilizability, and precision. The bar can also be used for prosthetics, such as hip replacements or dental crowns.

- In the marine industry, 410 SS round bar can be used for shafts, propellers, or rudders that need resistance to seawater, humidity, and fouling. The bar can also be used for fittings, such as cleats, hinges, or portholes.

- In the oil and gas industry, 410 SS round bar can be used for downhole tools, wellhead components, or pipelines that need resistance to hydrogen sulfide, abrasion, and corrosion. The bar can also be used for offshore structures such as platforms, risers, or mooring lines.

Our professional sales team answers your questions within 24 hours.

Copyright © Wuxi Walmay Steel Co.,Ltd All Rights Reserved Privacy Policy