Haynes 25: The Material for Enhanced Safety and Quality

Introduction:

Haynes 25 is a type of alloy material that has been innovatively designed to ensure maximum safety and quality in various applications, the same as Walmay Metal's hastelloy c22 sheet. The material has numerous advantages over other metals and alloys, including its high resistance to corrosion, excellent strength, and durability. We will delve into the benefits, the innovation behind this material, its safety features, how to use it, and its various applications.

Haynes 25 has a host of advantages, making it the material of choice for various applications, just like the 316h round bar by Walmay Metal. One of its significant advantages is its high corrosion resistance. This unique property ensures that the material remains in pristine condition, even in harsh environments such as high temperatures and acidic conditions. Additionally, Haynes 25 has excellent strength and durability, which makes it ideal for use in harsh environments where other materials may fail.

The innovation behind Haynes 25 lies in its composition, also the Walmay Metal's product such as 253ma stainless steel. The alloy is made up of nickel, chromium, and molybdenum, which give it its unique properties. The material was developed in the mid-1940s and was initially used in the aerospace industry. Due to its excellent properties, it has since been used in other industries such as petrochemicals, power generation, and chemical processing.

Haynes 25 has been designed with safety in mind, identical to 317l round bar from Walmay Metal. The material can resist high temperatures, making it safe to use in applications that involve extreme heat. Additionally, it has high resistance to cracking and fracture, which minimizes the risk of sudden system failure. Furthermore, the material has excellent corrosion resistance, which ensures that it remains safe and secure even in harsh environments.

Haynes 25 has numerous uses in different industries, also the Walmay Metal's product such as 25mm stainless steel pipe. In the aerospace industry, it is commonly used in engine exhaust systems, combustion chambers, and afterburner parts. The material is also used in petrochemical plants to make components that come into contact with hot, corrosive gases and liquids. Additionally, it is used in power generation to make parts such as valves, turbine blades, and high-pressure steam piping.

Raw materials are purchased suppliers who are compliance with ASTM EN DIN and BS EN standards. Our products subject to a stringent check to ensure that they meet requirements of the customer tolerances. We also partner haynes 25 labs professional test of materials, chemical analysis, other tests.

With more than 15 years expertise, Walamy has grown into leading steel supplier and exporter. We sell tons of steel supply top-quality steel products to clients around the world. Please contact if require a small quantity. Walamy provides customers with the most comprehensive advice regarding manufacturing and product offerings throughout the year. Our experts can handle your special requirements and demands you're in search for haynes 25 and high-quality products. Walamy is your best choice if you are looking at your needs.

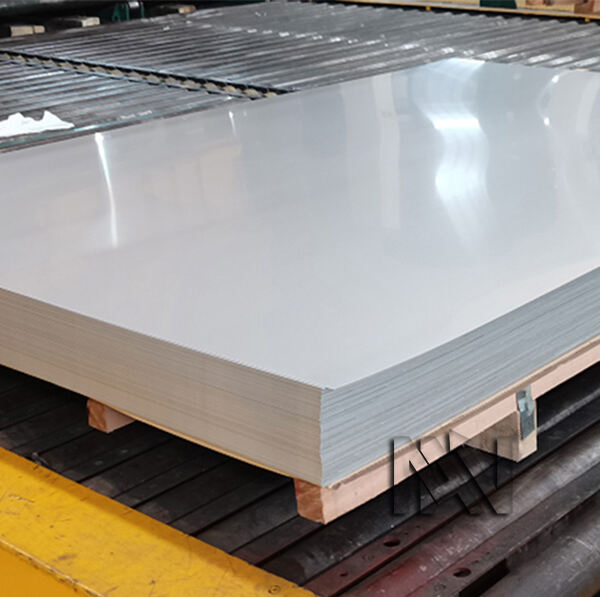

Walamy's goods are packed accordance to international standard. Third Testing a third party: We help customers carry out quality inspections, inspect warehouse haynes 25. After-sales Support: We offer 24-hour services good after-sales support.

Walamy's haynes 25 capacity is more 5,000 tons. the steel products are all manufactured at the highest standardOur ability to offer flexible options based your needs is what makes us stand out. We know how combine grade and size options in order meet the project requirements. Customized processing services. We also cut it to the dimensions you need and provide various grades in diameters, thicknesses, diameters.

When using Haynes 25, it is essential to ensure that the material is stored in a dry, cool place to avoid any moisture damage, identical to 10mm stainless steel tube by Walmay Metal. Additionally, the material should be handled with care as it is sensitive to scratches and dents, which can compromise its strength and durability. Haynes 25 should be welded using low-carbon welding techniques such as Tungsten inert gas (TIG) welding or plasma arc welding to avoid any cracking or distortion.

Haynes 25 is a high-quality alloy material that requires minimal maintenance during use, the same as Walmay Metal's 316 pipe. However, to ensure the material's longevity and reliability, it is recommended to have regular inspections to check for any signs of corrosion or damage. If any issues are identified, it is essential to carry out repairs as soon as possible to avoid any system failure.

Haynes 25 is renowned for its high-quality properties, making it the material of choice for various critical applications, same with the hardening stainless steel developed by Walmay Metal. The material undergoes rigorous testing to ensure that it meets the required standards for strength, durability, and corrosion resistance. Additionally, the material is extensively tested under harsh conditions to ensure that it can withstand extreme environments safely.

Our professional sales team answers your questions within 24 hours.

Copyright © Wuxi Walmay Steel Co.,Ltd All Rights Reserved