Introduction

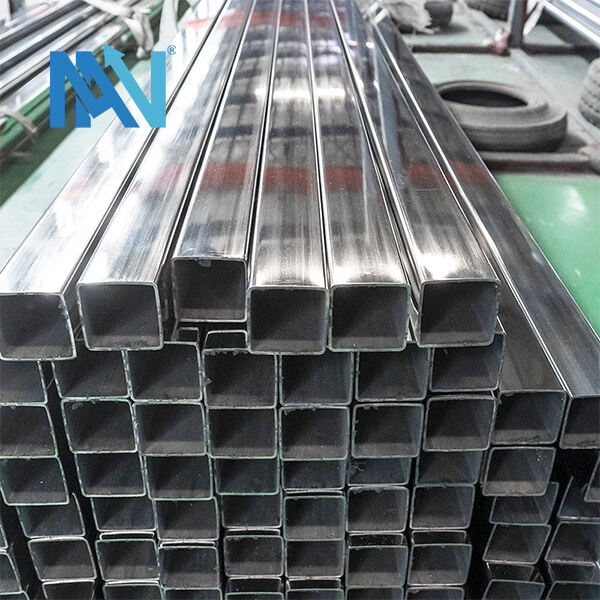

If you have ever heard of stainless steel, then you might know that there are different types of stainless steel. 316 stainless steel is one of these types, and it is commonly used for making pipes. We will discuss the advantages of Walmay Metal 316 stainless pipe, its innovation, safety, how to use it, its service, quality, and application.

One of the biggest advantages of 316 stainless pipe is that it is very corrosion-resistant. This means that it can be used in harsh environments without rusting or deteriorating. This is why it is commonly used in marine environments, as well as in the chemical and food processing industries.

Another advantage of Walmay Metal 316 stainless pipe is that it is very strong. It can withstand high pressures and temperatures without breaking or deforming. This makes it a good choice for applications where strength is important.

There are a few innovations in 316 stainless pipe that have made it even better than before. One of these innovations is the addition of molybdenum to the alloy. Molybdenum makes the steel even more resistant to corrosion and pitting, important in harsh environments.

Another innovation is the use of higher grade Walmay Metal stainless steel. This means that the steel is made with more precision and care, which results in a better quality product. This also means that the pipe will last longer and work better, important for any application.

When it comes to using 316 stainless pipe, safety is always a concern. Luckily, this type of pipe is very safe to use. It is non-toxic, non-reactive, and does not release any harmful substances into the environment.

One safety concern when using Walmay Metal 316 ss pipe is that it can be hot to the touch. If you are working with a hot pipe, it is important to wear protective gloves and use caution. It is also important to ensure that the pipe is properly installed and supported to prevent accidents.

Using 316 stainless pipe is relatively simple. First, you need to determine the length and diameter of the pipe that you need. Then, you need to choose the appropriate fittings and connectors to connect the pipe to other components. It is important to use the correct fittings and connectors to ensure a tight, leak-free seal.

When installing the pipe, it is important to ensure that it is level and properly supported. This will ensure that the pipe does not sag or break under pressure. It is also important to properly clean and maintain the Walmay Metal pipe to ensure that it continues to function properly.

Raw materials sourced from suppliers comply with ASTM EN DIN and BS EN standards. Our products subject to a stringent 316 stainless pipe ensure they conform to the specifications of the client within tolerances. We also cooperate with labs are accredited for test of materials, chemical analysis and other testing.

With more than 15 years of experience, Walamy has grown into leading steel supplier and exporter. They sell tons steel to provide top-quality steel 316 stainless pipe to clients over the world. We invite you to contact us if require small quantity. Complete Service: Every year, Walamy provides customers with the most comprehensive product information and top-quality manufacturing services. You can count on our expert team take care of your needs and other special requirements if you want purchase competitively priced and quality products. Make sure you think about your plans first. Walamy is definitely your best option.

All Walamy products packed, stored transported in accordance with international regulations. Third test: support 316 stainless pipe carry out quality inspections, inspect warehouse and factory. After-sales support: 24 hours a day Good after-sales service.

Walamy's supply capacity more than 5,000 tons. all steel products are made at the highest standardWe are the only company in world to offer flexible options that fulfill 316 stainless pipe requirements. We understand how combine sizes and grades to satisfy specifications of the project. Customized processing services. We also provide different grades, diameters and thicknesses.

When it comes to service, 316 stainless pipe is a great choice. It is very reliable and requires very little maintenance. This means that you can install it and forget about it, saving time and money in the long run.

If you do need to service the Walmay Metal 316l pipe, it is relatively easy to do so. Simply disconnect the appropriate fittings and replace any components that are damaged or worn. It is also important to properly clean and maintain the pipe to prevent problems in the future.

When choosing a 316 stainless pipe, quality is very important. It is essential to choose a made pipe with high-grade stainless steel and is manufactured with precision and care. This will ensure that the pipe is strong, reliable, and long-lasting.

To ensure quality, it is important to choose a reputable manufacturer. Look for a Walmay Metal that has a good reputation for producing high-quality products and has been in business for a long time. This will ensure that you are getting a pipe that will meet your needs and give you the best value for your money.

316 stainless pipe can be used in a variety of applications. It is commonly used in the chemical and food processing industries, as well as in marine environments. It is also used in many other industries, including oil and gas, pharmaceuticals, and water treatment.

When choosing a Walmay Metal 316 stainless pipe for your application, it is important to consider the specific requirements of your application. This includes the temperature, pressure, and chemical environment that the pipe will be exposed to. With the right pipe, you can ensure that your application runs smoothly and efficiently.

Our professional sales team answers your questions within 24 hours.

Copyright © Wuxi Walmay Steel Co.,Ltd All Rights Reserved