Haynes 25 alloy rod is a Co-Cr-Ni based solid solution strengthened deformed high-temperature alloy with a service temperature below 1000°C. Add w(Cr) 20% and w(W)15% to Haynes 25 alloy rod for solid solution strengthening. Haynes 25 alloy rod has medium durability and creep strength below 815℃, excellent oxidation resistance below 1090℃, and has good processing and welding performance.

Haynes 25 alloy rod is very sensitive to the content of silicon element. Silicon can promote the formation of Co2W type Laves phase when the alloy is exposed between 760°C and 925°C, thus reducing the room temperature plasticity of the alloy. Therefore, ω (Si) should be controlled in the alloy.<0.4%.

Specifications |

In stock, can be customized according to customer requirements |

Form |

Plate,Bar |

Classification |

Haynes alloy |

Density(g/cm³) |

Melting point |

9.13 |

1330-1410℃ |

C |

Cr |

Ni |

W |

Co |

Mn |

Fe |

Si |

P |

S |

0.05~0.15 |

19.0~21.0 |

9.0~11.0 |

14.0~16.0 |

Balance |

1.0~2.0 |

≤3.0 |

≤0.40 |

≤0.04 |

≤0.03 |

Variety |

Heat treatment method |

Yield Strength(R0.2/ MPa) |

Tensile strength(R m /MPa) |

Elongation δ5 /% |

Brinell Hardness(HB) |

Rod |

Solution treatment |

≥860 |

≥340 |

≥35 |

≤282 |

Ring piece |

Solution treatment |

≥860 |

≥340 |

≥35 |

≤282 |

Haynes 25 alloy Baris suitable for working in jet engines, gas turbines and marine atmospheres. The minimum temperature of resistance to oxidation and carbonization is 870°C when working under intermittent conditions, and it can withstand 1090°C when working continuously under air conditions. high temperature.

Haynes 25 alloy Barsare mainly used on imported machines to manufacture high-temperature parts such as guide vanes, turbine outer rings, outer walls, vortexers, and sealing blades. This alloy is very sensitive to silicon content. Silicon can promote the formation of Co2W type L phase when the alloy is exposed between 760 and 925°C, thereby reducing the room temperature plasticity of the alloy. Therefore, the silicon content in the alloy should be controlled to less than 0.4%.

Haynes 25 partsheat treatment process:

Forged rods and forgings: 1230°C, water cooling; medium plates: 1200°C, water cooling; sheets and strips: 1170~1200°C, water cooling or rapid air cooling.

The moisturizing time is about 1 hour for every 25mm of thickness, but at least 15mm.

The rivets should be solution treated at 1160~1190℃ for 10~20 minutes, followed by water cooling or rapid cooling.

The manufacturing process of stainless steel and alloys involves multiple steps to transform raw materials into flat,rectangular sheets or plates made of stainless steel and alloys. Here are a few key steps for stainless steel and alloys:

Molten stainless steel and alloys are cast into large ingots or billets through a casting process.

During the hot rolling process,the thickness of the steel ingot is gradually reduced and elongated to form long strips or coils.

Annealing involves heating stainless steel and alloys to a specific temperature and then slowly cooling it.

Cold rolling is carried out through rolling mills to reduce thickness to meet customer specifications.

Wuxi Walmay Metal Co,Ltd is a comprehensive processing group of Alloy Steel、Forged Parts Fitting、Titanium Alloy、Stainless Steel、Special Welding Wireseries, and more than 800 specifications.

Our group has been engaged in the domestic and global market for more than ten years with rich steel experience and can offer professional advice for customers inapplications with different materials.

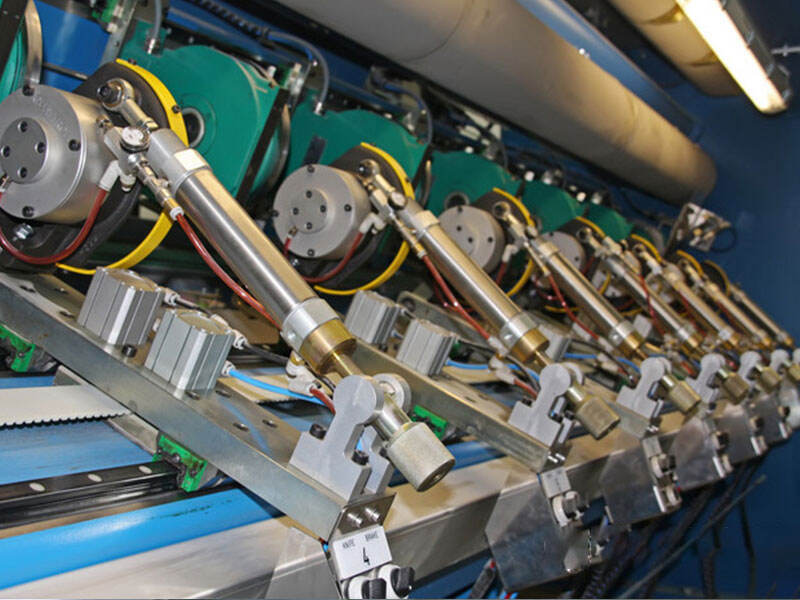

Machine cutting

Sheet cutting

plasma cutting

Dynamic waterjet cutting

sawing

Plank leveling

polishing

laser cutting

laser cutting

production cutting

Long product cutting

Bar and structural cutting

polishing

Heat treatment and annealing: Wuxi Walmay Metal can heat treat certain 400 series stainless steels.

Material Reliability Identification (PMI): Wuxi Walmay Metal can complete this testing in-house.

Ut Testing: Ultrasonic testing (UT) uses high-frequency sound energy to inspect and measure stainless steel products.

Our professional sales team answers your questions within 24 hours.

Copyright © Wuxi Walmay Steel Co.,Ltd All Rights Reserved