310S stainless steel is a low-priced high-temperature resistant stainless steel material. The maximum operating temperature of the material can reach 1200 ℃, and the continuous operating temperature is 1150 ℃. It is currently the first choice for low-corrosion environment and high-temperature-resistant metal materials in the chemical industry. On the basis of 310, 310S reduces the carbon and sulfur content, reduces the possibility of embrittlement of the material in high-temperature use environments, and avoids the generation of excessive secondary cementite and σ phase during the welding process.

Specifications |

In stock, can be customized according to customer requirements |

Form |

Plate,Strip,Bar,Pipe |

Classification |

Stainless steel austenitic |

Type |

310SStainless steel Coil |

Grade |

201, 202, 204 Cu3, 301, 304, 304L, 310S, 316L, 321, 409L, 410S, 420J2, 430, 439, 441, 444, 445 |

Surface Finish |

2B, 2D, BA, No.3, No.4, No.5, SB, HL |

Thickness |

0.3~3.0 mm |

Length |

no defined |

Width |

610~1524 mm |

Inner Diameter |

610 or 508 +0/-5 mm |

Width Tolerance |

Mill Edge:Aim ±10;Cut Edge:Aim ±10,Aim -0 / +1 |

Standard |

AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc |

MOQ |

1 ton , We can accept sample order. |

Delivery port: |

Shanghai, Tianjin, Qingdao, Ningbo, Guangzhou, etc. |

Packaging Detail |

Standard export packaging, various transportation, according to customer needs |

Grade |

C |

Si |

Mn |

Cr |

Ni |

S |

P |

Mo |

N |

316L |

≤0.03 |

≤1.00 |

≤2.00 |

16.00~18.00 |

10.0-14.0 |

≤0.03 |

≤0.045 |

2.0-3.0 |

- |

316 |

≤0.08 |

≤1.00 |

≤2.00 |

16.00~18.00 |

10.0-14.0 |

≤0.03 |

≤0.045 |

2.0-3.0 |

- |

310S |

≤0.08 |

≤1.5 |

≤2.00 |

24.00~26.00 |

19.0-22.0 |

≤0.03 |

≤0.035 |

- |

- |

Grades |

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

Elongation(50mm)/% |

HB |

HRB |

HV |

316L |

≥480 |

≥177 |

≥40% |

≤187 |

≤90 |

≤200 |

316 |

≥520 |

≥205 |

≥40% |

≤187 |

≤90 |

≤200 |

310S |

≥515 |

≥205 |

≥40% |

≤217 |

≤95 |

≤225 |

310S stainless steelis a high-temperature corrosion-resistant stainless steel material that is usually used to manufacture components and equipment that work at high temperatures, such as furnaces, heat treatment equipment, chemical reactors, etc. 310S stainless steel is widely used in boilers, chemical heaters, plate heat exchangers, boilers, heaters, chemical high-temperature environment equipment, automobile purification devices, etc.

310S stainless steel plate: usually used to make storage tanks, heat exchangers, chemical equipment and other components.

310S stainless steel pipe:can be used to transport high-temperature, high-pressure fluids or gases, and is suitable for chemical, petroleum, natural gas and other fields.

310S stainless steel bars:can be made into bolts, nuts, bearings and other parts, and can also be used as raw materials for mechanical processing.

310S stainless steel wire:can be made into springs, nets, filters and other products, and can also be used in the manufacture of electronic components.

The manufacturing process of stainless steel and alloys involves multiple steps to transform raw materials into flat,rectangular sheets or plates made of stainless steel and alloys. Here are a few key steps for stainless steel and alloys:

Molten stainless steel and alloys are cast into large ingots or billets through a casting process.

During the hot rolling process,the thickness of the steel ingot is gradually reduced and elongated to form long strips or coils.

Annealing involves heating stainless steel and alloys to a specific temperature and then slowly cooling it.

Cold rolling is carried out through rolling mills to reduce thickness to meet customer specifications.

Wuxi Walmay Metal Co,Ltd is a comprehensive processing group of Alloy Steel、Forged Parts Fitting、Titanium Alloy、Stainless Steel、Special Welding Wireseries, and more than 800 specifications.

Our group has been engaged in the domestic and global market for more than ten years with rich steel experience and can offer professional advice for customers inapplications with different materials.

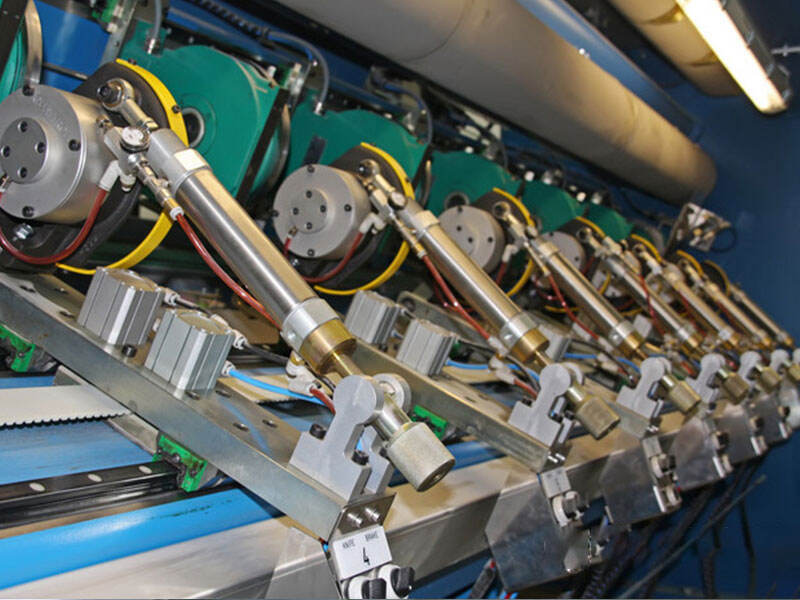

Machine cutting

Sheet cutting

plasma cutting

Dynamic waterjet cutting

sawing

Plank leveling

polishing

laser cutting

laser cutting

production cutting

Long product cutting

Bar and structural cutting

polishing

Heat treatment and annealing: Wuxi Walmay Metal can heat treat certain 400 series stainless steels.

Material Reliability Identification (PMI): Wuxi Walmay Metal can complete this testing in-house.

Ut Testing: Ultrasonic testing (UT) uses high-frequency sound energy to inspect and measure stainless steel products.

Our professional sales team answers your questions within 24 hours.

Copyright © Wuxi Walmay Steel Co.,Ltd All Rights Reserved